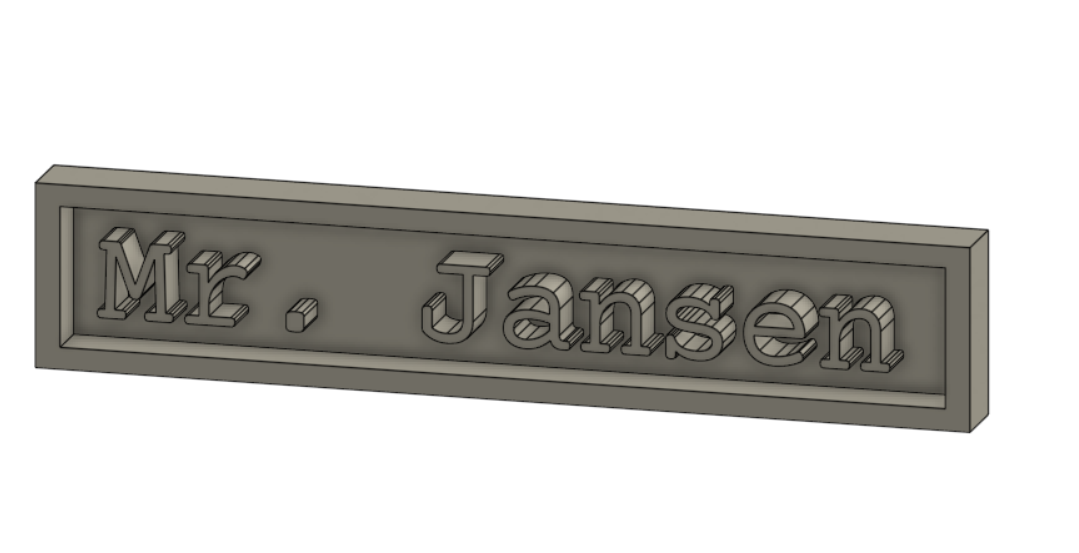

CNC'd Nameplate

Overview

Designed and machined a custom aluminum nameplate using a CNC mill, applying CAD/CAM principles from start to finish. Gained hands-on experience with digital manufacturing workflows, toolpath optimization, and post-processing techniques.

Design Process

- Created a detailed parametric 3D model in Onshape

- Generated 2D toolpaths for roughing and finishing operations

- Simulated machining operations to ensure tool clearance and surface finish

- Refined design based on tool/material limitations and machining constraints

CAD model

Machining Process

- Milled from a solid chunk of pine using Axiom CNC machine

- Roughing Pass: 1/4" flat end mill to remove bulk material

- Finishing Pass: 1/8" ball end mill to achieve smooth engraved features

- Manually deburred and polished the final piece for a clean, professional finish

Final Result

Polished pine nameplate with custom engraved text. This project reinforced my understanding of manufacturing, tool selection, and precision machining workflows.